Posts: 817

Threads: 45

Likes Received: 2,159 in 653 posts

Likes Given: 2,310

Joined: Apr 2019

Location The Netherlands

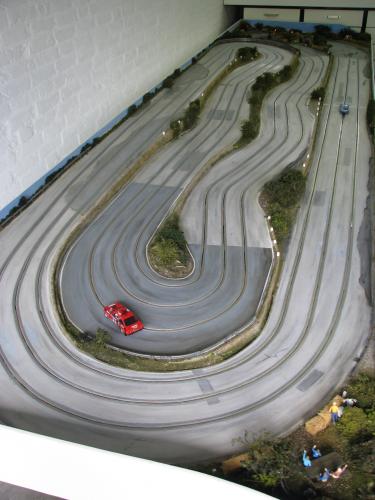

In 2006 the Dutch Trio Track started "live" as a copper taped track.

After six years, the copper tape had to be repaired so often that I decided to go for braids.

Here is a photo report about that replacement:

Hub

The condition of the copper tape before it was replaced with braids.

The removing of the damaged copper tape. Cutting one side of the braids chambers with a simple handmade tool.

(block of wood and 3 mm pin)

Posts: 817

Threads: 45

Likes Received: 2,159 in 653 posts

Likes Given: 2,310

Joined: Apr 2019

Location The Netherlands

Posts: 1,421

Threads: 216

Likes Received: 2,118 in 775 posts

Likes Given: 1,027

Joined: Mar 2019

Location Norfolk, England

How did the copper tape get in such a terrible state Hub? In over ten years I have only had one breakage on my track, due to the MDF board shifting slightly. The rest is as good as the day it was laid.

![[+]](https://slotracer.online/community/images/bootbb/collapse_collapsed.png) •

•

Posts: 817

Threads: 45

Likes Received: 2,159 in 653 posts

Likes Given: 2,310

Joined: Apr 2019

Location The Netherlands

Hi Brian,

I think the temperature in my non-insulated flat roof garage fluctuates more.

The garage is placed against the house on one side only.

When not in use, my racetrack is positioned vertically against the outer non-insulated garage wall (the longest wall without a door).

In winter it can freeze and in summer the temperature can rise above 40

°C, after the hot car has been parked inside.

There are always forces on the copper tape adhesive in that vertical position

But maybe my choice of copper tape was wrong or it was just bad luck.

I used copper foil tape 13/64"x36YDS 5.2mm (.00125).

The copper taped Trio Track ready for use. The hot car parked right next to the vertically tilted track.

(This post was last modified: 22nd-Jun-21, 12:35 PM by

rallyhub.)

Posts: 817

Threads: 45

Likes Received: 2,159 in 653 posts

Likes Given: 2,310

Joined: Apr 2019

Location The Netherlands

Posts: 817

Threads: 45

Likes Received: 2,159 in 653 posts

Likes Given: 2,310

Joined: Apr 2019

Location The Netherlands

Here's the final batch of photos about the change from copper tape to braids on the Trio Track.

I hope you liked the photo report.

Hub

Connection to the cabling. One lane done, two more to go.

All three lanes ready. Braids on the Trio Track. View from Ruin Bend.

Posts: 83

Threads: 2

Likes Received: 162 in 53 posts

Likes Given: 117

Joined: Sep 2020

Location Tampa, FL

Really nice track! I'm about to embark on going from copper tape to braid as well for similar reasons: Florida heat/humidity is making the tape lift continually.

I am amazed and impressed regarding you routing the gains for the braid by hand - WOW! I'm going to be cheating and using a special, fluted routing bit for that on mine and will post pictures once done.

A quick question: the picture labeled "Connection to the cabling" - how did you cut those nice, thin openings? I'd like to have mine look the same!

Posts: 817

Threads: 45

Likes Received: 2,159 in 653 posts

Likes Given: 2,310

Joined: Apr 2019

Location The Netherlands

The reason for doing the entire routing by hand was the lack of space in some places between the outer slots and the landscape.

The thin openings were made with a small flat file.

Success with your change to braid. I look forward to seeing the pictures about it.

Hub

Not enough space between the inner slot and the border for using a router. The thin openings are made with a small flat file (photo of another track).

Posts: 384

Threads: 23

Likes Received: 510 in 191 posts

Likes Given: 715

Joined: Dec 2021

Location Cowplain, Hampshire UK

(22nd-Jun-21, 12:27 PM)rallyhub Wrote: Hi Brian,

I think the temperature in my non-insulated flat roof garage fluctuates more.

The garage is placed against the house on one side only.

When not in use, my racetrack is positioned vertically against the outer non-insulated garage wall (the longest wall without a door).

In winter it can freeze and in summer the temperature can rise above 40°C, after the hot car has been parked inside.

There are always forces on the copper tape adhesive in that vertical position

But maybe my choice of copper tape was wrong or it was just bad luck.

I used copper foil tape 13/64"x36YDS 5.2mm (.00125).

The copper taped Trio Track ready for use. The hot car parked right next to the vertically tilted track.

Hi hub, I love how you have made this track so you can fold it away.

Have you done a complete build thread on this?

It's the solution for what I want to do in my garage, so many questions like how things are fitted to the board and don't move when folded away.

I would love to see any construction pics if you're willing to share.

Cheers

Tony

(This post was last modified: 27th-Dec-21, 06:53 PM by

Tibbs.)

![[+]](https://slotracer.online/community/images/bootbb/collapse_collapsed.png) •

•

Posts: 1,883

Threads: 170

Likes Received: 2,310 in 914 posts

Likes Given: 2,247

Joined: Mar 2019

Location Overijse, Belgium

Wonderful work hub!! Looking forward to seeing the scenery going up

![[+]](https://slotracer.online/community/images/bootbb/collapse_collapsed.png) •

•

![[+]](https://slotracer.online/community/images/bootbb/collapse_collapsed.png)