Posts: 536

Threads: 31

Likes Received: 795 in 354 posts

Likes Given: 190

Joined: Dec 2020

Location burnley UK

hi guys

advice needed

i am having real trouble truing the softer rubber tyres

they are just ' chewing up ' when i try

i have a 'TYRE TRUE' truer

the same as a razor

i run at low volts , slow speed and minimal amp usage as directed on many youtube vids

but the tyres start to chew up and rip ?

any help appreciated ... i have ruined 3x sets of tyres so far , 1x thunderslot TYROO5RX and 2x NSR ULTRA

my wallet will be truely grateful

kev

Posts: 1,963

Threads: 119

Likes Received: 3,233 in 1,323 posts

Likes Given: 2,824

Joined: Sep 2020

Location A small igloo in Canada

Hi Kev,

Can you try changing to a much finer grit surface and take more time?

Just an idea.

![[+]](https://slotracer.online/community/images/bootbb/collapse_collapsed.png) •

•

Posts: 537

Threads: 22

Likes Received: 822 in 379 posts

Likes Given: 348

Joined: Jun 2019

Less pressure

Less speed

Use zippo fluid as a lubricant. Put it on he tyres and the grit surface and don't let it dry out while working the tyre.

True for 15 seconds, pause, restart...

Don't dump the tyres you think you've ruined. They are likely to be recoverable.

Alan W

![[+]](https://slotracer.online/community/images/bootbb/collapse_collapsed.png) •

•

Posts: 536

Threads: 31

Likes Received: 795 in 354 posts

Likes Given: 190

Joined: Dec 2020

Location burnley UK

hi alan

tried all 3

the problem is keeping the grit surface ON the grinding plate when using lighter fluid , it eats the adhesive tape almost immediately

any tips for the grit , grades / types to use and / or the method to keep it attached to the plate ?

also ken , i found ( wierdly ) finer grit was worse ?

have tried quite a large range so far :(

![[+]](https://slotracer.online/community/images/bootbb/collapse_collapsed.png) •

•

Posts: 3,836

Threads: 647

Likes Received: 8,295 in 2,945 posts

Likes Given: 8,825

Joined: Apr 2019

Location Worthing, UK

The Thunderslot tyres are notoriously difficult to true and most people don’t bother. The NSR ultras are okay in my experience - and definitely need truing. I’m using 400 or 600 grit paper glued flat on the mdf plate of my

DIY truer, with the tyres powered by the car at 12 volts. That means it’s very gentle pressure for 5 seconds on the paper and then lift... That’s needed to protect the motor, but it’s helping the tyres also. I don’t use any liquid, I just go very gently and patiently.

(This post was last modified: 11th-Mar-21, 10:43 PM by

woodcote.)

Posts: 537

Threads: 22

Likes Received: 822 in 379 posts

Likes Given: 348

Joined: Jun 2019

(11th-Mar-21, 08:22 PM)OXO cube Wrote: the problem is keeping the grit surface ON the grinding plate when using lighter fluid , it eats the adhesive tape almost immediately

Sorry about that. Unexpected.

I use a large sheet and true in a similar way to Andy's DIY truer above.

Maybe you are using too much zippo?

"Damp", not "soaked" is how it should be

(This post was last modified: 12th-Mar-21, 07:37 AM by

Nonfractal.)

![[+]](https://slotracer.online/community/images/bootbb/collapse_collapsed.png) •

•

Posts: 118

Threads: 8

Likes Received: 176 in 70 posts

Likes Given: 65

Joined: Apr 2019

Hold up, for me, there are some pieces of information missing

1) How do you glue the tyres on the wheels, and how do you apply the glue

2) - is the glue holding consistently, or are some parts of the outside edges coming unglued.

2) What glue do you use - is it reacting with the tyres, making them more prone to splitting

3) What voltage are you running the tyre true at?

4a) What is the amperage load when free spinning before the tyre touches the plate

4b) What is the amperage load when the tyre touches the plate

FWIW, When I use my RSM - same system, and very similar to the tyre true, which morphed into the Professor Motor 1401 lathe when Pete sold them the tooling and parts, I am watching current draw and RPM drop like a bomb squad guy watching a mercury switch when he cuts the wires.

And I only have about 240 grit on the plate, and almost never use any fluid - certainly not needed when doing an ultra-grip.

Posts: 1,900

Threads: 171

Likes Received: 2,362 in 928 posts

Likes Given: 2,298

Joined: Mar 2019

Location Overijse, Belgium

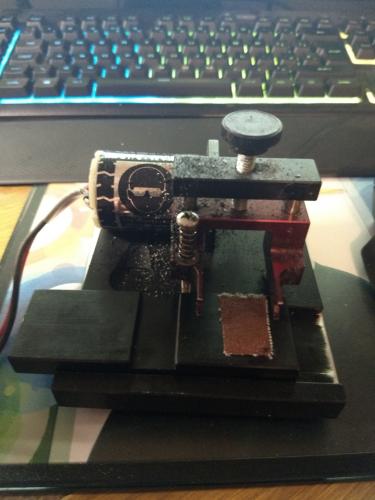

Can you put up a picture of your tyre truer please?

Will be able to then better understand possible issues....

![[+]](https://slotracer.online/community/images/bootbb/collapse_collapsed.png) •

•

Posts: 34

Threads: 2

Likes Received: 57 in 25 posts

Likes Given: 26

Joined: Jan 2021

(11th-Mar-21, 10:34 PM)woodcote Wrote: The Thunderslot tyres are notoriously difficult to true and most people don’t bother. The NSR ultras are okay in my experience - and definitely need truing. I’m using 400 or 600 grit paper glued flat on the mdf plate of my DIY truer, with the tyres powered by the car at 12 volts. That means it’s very gentle pressure for 5 seconds on the paper and then lift... That’s needed to protect the motor, but it’s helping the tyres also. I don’t use any liquid, I just go very gently and patiently.

'Zactly! ... and Touche Andy.

Tool speed, technique, and voodoo mean nothing without patience

Where some must die, so that others may live.

Posts: 536

Threads: 31

Likes Received: 795 in 354 posts

Likes Given: 190

Joined: Dec 2020

Location burnley UK

(12th-Mar-21, 08:12 AM)slotloco Wrote: Hold up, for me, there are some pieces of information missing

1) How do you glue the tyres on the wheels, and how do you apply the glue apply to wheel rim , them wipe away excess

2) - is the glue holding consistently, or are some parts of the outside edges coming unglued. glue is uniform and tyres stay in position

2) What glue do you use - is it reacting with the tyres, making them more prone to splitting nail varnish , no apparent issues

3) What voltage are you running the tyre true at? between 5-7 v

4a) What is the amperage load when free spinning before the tyre touches the plate cant remember , i true in garage and its freezing atm ... so im not checking hehehe

4b) What is the amperage load when the tyre touches the plate the moment i see a load change , i true until the load returns to the 'no load' amps

FWIW, When I use my RSM - same system, and very similar to the tyre true, which morphed into the Professor Motor 1401 lathe when Pete sold them the tooling and parts, I am watching current draw and RPM drop like a bomb squad guy watching a mercury switch when he cuts the wires.

And I only have about 240 grit ( this looks to be the difference im using 600 grit as my roughest surface ) on the plate, and almost never use any fluid - certainly not needed when doing an ultra-grip.

this is my truer Anthony

and a pic of the thunderslot tyre ( the biggest problem ) .... its like its being torn when truing ... pulling maybe 0.3mm chunks outa the tyre surface

one thing I'm not lacking in is patience ... but these tyres are testing me

![[+]](https://slotracer.online/community/images/bootbb/collapse_collapsed.png) •

•

![[+]](https://slotracer.online/community/images/bootbb/collapse_collapsed.png)