10th-Sep-25, 01:15 AM

Hi Guys.

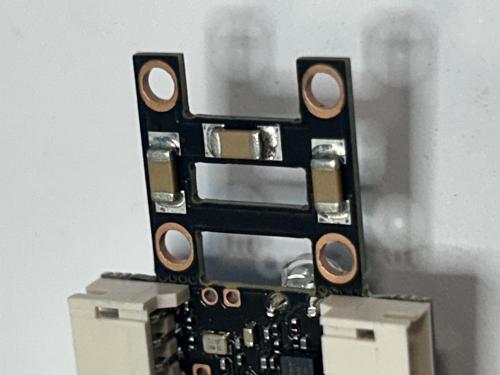

If you have a Carrera digital car you will have one of these as standard.

However any other brand will require a motor arrestor. It smooths any back emf spiking back into the decoder via the back door and momentarily upsetting the microprocessor. This can cause glitches in how the car operates.

Previously Ade Judge developed his own solution which he shared. And this is just a neater more professional product on a tiny PCB.

It comes standard as a snap off when you buy any Scorpius MPD decoder.

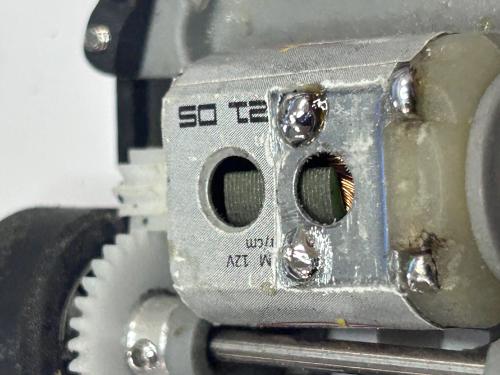

I used a Thunderslot 21.5K can but the principal is the same for most motors.

First of all take your MPD

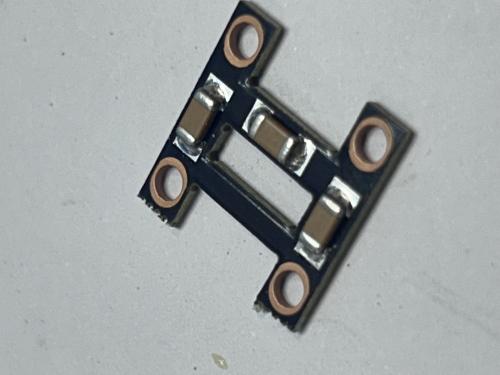

Then snap off. I actually use small sharp side cutters to cut off.

Next remove the paper with a modelling knife and use a dremel to rough up 2 tiny areas where the solder pads will sit.

Then I use a 15W soldering iron minimum to tin 2 pads. While I’m at it I’ll re-tin the wire pads with fresh solder.

Next tin the arrestor.

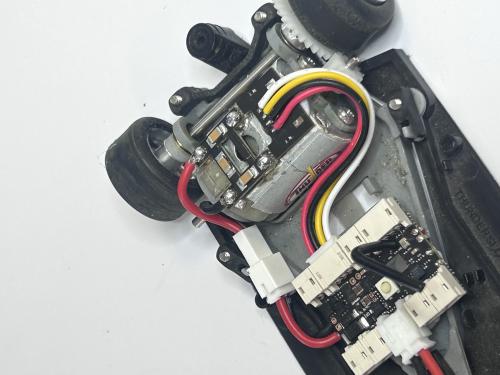

Next I add a tiny dab of white nail polish to motor comm as shown for the tacho.

Then super glue the tacho PCB to the motor can so the sensors are directly over the white marker.

Plug and play. Just connect to data port. Default is port 2 but you configure the MPD to choose any port you like.

If you have a Carrera digital car you will have one of these as standard.

However any other brand will require a motor arrestor. It smooths any back emf spiking back into the decoder via the back door and momentarily upsetting the microprocessor. This can cause glitches in how the car operates.

Previously Ade Judge developed his own solution which he shared. And this is just a neater more professional product on a tiny PCB.

It comes standard as a snap off when you buy any Scorpius MPD decoder.

I used a Thunderslot 21.5K can but the principal is the same for most motors.

First of all take your MPD

Then snap off. I actually use small sharp side cutters to cut off.

Next remove the paper with a modelling knife and use a dremel to rough up 2 tiny areas where the solder pads will sit.

Then I use a 15W soldering iron minimum to tin 2 pads. While I’m at it I’ll re-tin the wire pads with fresh solder.

Next tin the arrestor.

Next I add a tiny dab of white nail polish to motor comm as shown for the tacho.

Then super glue the tacho PCB to the motor can so the sensors are directly over the white marker.

Plug and play. Just connect to data port. Default is port 2 but you configure the MPD to choose any port you like.

www.scorpiuswireless.com

![[+]](https://slotracer.online/community/images/bootbb/collapse_collapsed.png)