1st-Nov-23, 08:09 PM

Flying Fiona 1929 Fiat

3rd-Nov-23, 05:59 PM

Hello Tony,

Did you make the motor/axle bracket. If you bought it, where please?

Leo

Did you make the motor/axle bracket. If you bought it, where please?

Leo

Forum Precepts: Don't hijack or divert topics - create a new one. Don't feed the Troll. http://www.scuderiaturini.com

3rd-Nov-23, 06:11 PM

(3rd-Nov-23, 05:59 PM)Scuderia_Turini Wrote: Hello Tony,

Did you make the motor/axle bracket. If you bought it, where please?

Leo

Hi Leo,

I brought the motor bracket at Orpington swap meet, I brought a handful.

I've had to turn up some bushings for 3/32 axle as these must of been for something bigger.

Here's a pic before I soldered them.

I wish there was someone here who sells them, I know there's a place in the states that does but as you know postage is stupid money from there.

cheers

Tony

6th-Nov-23, 01:52 PM

Slot.It make 9 and 10 tooth brass pinions with a 1.5mm bore to suit FF/FK motors. Pendle sells them.

Mike

Mike

6th-Nov-23, 03:46 PM

This place has a large selection of brass motor brackets. Sorry, they're in the USA. Talk with some friends and order enough to make it worth your while.

https://e-slotcar.com/search.php?search_...on=product

https://e-slotcar.com/search.php?search_...on=product

6th-Nov-23, 09:17 PM

(6th-Nov-23, 03:46 PM)KensRedZed Wrote: This place has a large selection of brass motor brackets. Sorry, they're in the USA. Talk with some friends and order enough to make it worth your while.

https://e-slotcar.com/search.php?search_...on=product

Thanks Ken,

I'll stock up on as many as I can find at swap meets here in Blighty when they come up.

6th-Nov-23, 09:17 PM

14th-Nov-23, 04:37 PM

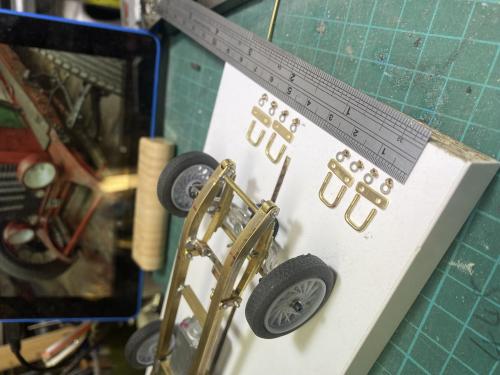

A little bit more progress on the suspension.

I brought some 1.2mm brass rod and some 2mm brass square bar.

The rod I threaded the ends and then cut and bent to make some u-bolts.

I didn't want to make a order of just 1.2mm threaded nuts from Prime miniatures so I decided to try and make my own nuts, hence the 2mm brass square bar.

I'm still learning on my little lathe, so the drilling and tapping of the square stock was heaps of fun, when I remembered to breath

I brought a jewellery's mini saw to cut the nuts as the smallest hack saw I have the blade was way too thick.

I was over the moon when they actually worked, a little filing and they do the job nicely.

Then I used my little bench cutter to make the small plates.

I didn't have a 2mm spanner so I ground down this little thing I found and it fits well into the end of a exacto handle.

They do exactly what I was hoping and I think look the part too.

Now I need to sort the back wheels.

The George Turner ones I'm using are only slip on and glue, but I want to be able to grub screw them on.

I've looked on Pendles and they have nice ali ones but they are almost 2mm shorter in height and that will just look wrong.

I'm thinking of somehow routeing the wheels out like I did on the fronts, and trying to turn a ali insert which will have a fake drum break.

That way I can tap a grub screw through to the axle.

I'm a novice on the mini lathe so I want to get better and how else can you if you don't try.

Thanks for looking.

I brought some 1.2mm brass rod and some 2mm brass square bar.

The rod I threaded the ends and then cut and bent to make some u-bolts.

I didn't want to make a order of just 1.2mm threaded nuts from Prime miniatures so I decided to try and make my own nuts, hence the 2mm brass square bar.

I'm still learning on my little lathe, so the drilling and tapping of the square stock was heaps of fun, when I remembered to breath

I brought a jewellery's mini saw to cut the nuts as the smallest hack saw I have the blade was way too thick.

I was over the moon when they actually worked, a little filing and they do the job nicely.

Then I used my little bench cutter to make the small plates.

I didn't have a 2mm spanner so I ground down this little thing I found and it fits well into the end of a exacto handle.

They do exactly what I was hoping and I think look the part too.

Now I need to sort the back wheels.

The George Turner ones I'm using are only slip on and glue, but I want to be able to grub screw them on.

I've looked on Pendles and they have nice ali ones but they are almost 2mm shorter in height and that will just look wrong.

I'm thinking of somehow routeing the wheels out like I did on the fronts, and trying to turn a ali insert which will have a fake drum break.

That way I can tap a grub screw through to the axle.

I'm a novice on the mini lathe so I want to get better and how else can you if you don't try.

Thanks for looking.

14th-Nov-23, 05:36 PM

lovely work

just an fyi :- UK motor brackets can be found here

Chassis (abslotsport.biz)

Kev

just looked and only see the offset bracket atm ? or are my eyes getting even worse :)

just an fyi :- UK motor brackets can be found here

Chassis (abslotsport.biz)

Kev

just looked and only see the offset bracket atm ? or are my eyes getting even worse :)

« Next Oldest | Next Newest »

Possibly Related Threads...

Thread / Author

Replies

Views

Last Post

Users browsing this thread: 1 Guest(s)

![[+]](https://slotracer.online/community/images/bootbb/collapse_collapsed.png)